What are the advantages of micro-CT as a research tool?

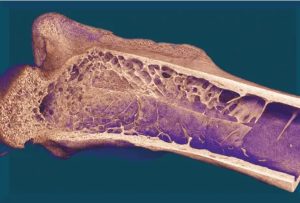

Micro-CT provides distinct advantages over other imaging modalities, delivering high-resolution, non-destructive, three-dimensional volumetric data of internal structures without the need for extensive sample preparation. This capability enables precise analysis of materials and biological tissues at the microscopic scale, while visualization of the specimen in its native state offers deeper insight into the inherent complexity and true nature of the material or tissue.

Figure 1: Micro-CT scan of a mouse femur, showing cortical and trabecular bone

Why is micro-CT non-destructive to samples?

Unlike some other high-resolution techniques that require slicing or cutting, micro-CTs can image samples without destroying them, allowing for continued use or further analysis. Micro-CT generally requires little to no sample preparation, such as drying or coating, unlike techniques like SEM, which need these steps for proper imaging. Therefore, CT imaging is commonly used in conjunction with other techniques to reinforce scientific findings and conclusions.

Micro-CT captures 2D X-ray projection images from a rotating sample, reconstructs them into layers of cross-sectional 2D images, and creates a 3D model from stacking the 2D slices, thus allowing for the visualization and analysis of a sample’s internal structure in its entirety, without destroying the sample.

How does micro-CT compare to clinical CT machines for high resolution?

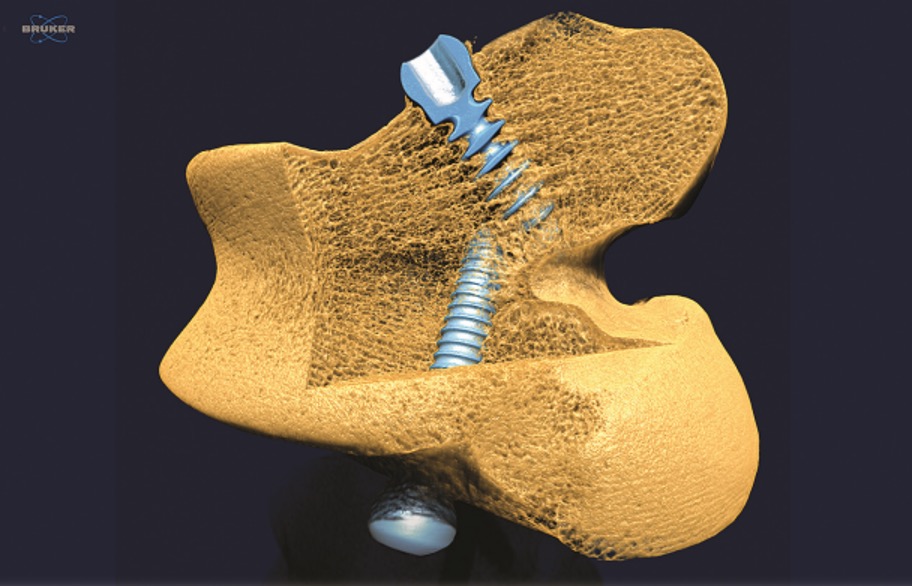

Standard clinical CT machines can only achieve resolution from 200-500 µm, making them unsuitable for most laboratory research. The Bruker Micro-CT desktop models can achieve resolutions in the single micron level and the SkyScan 2214 can push that boundary for true submicron resolution (Figure 2).

What is the advantage of a large Field of View (FOV)?

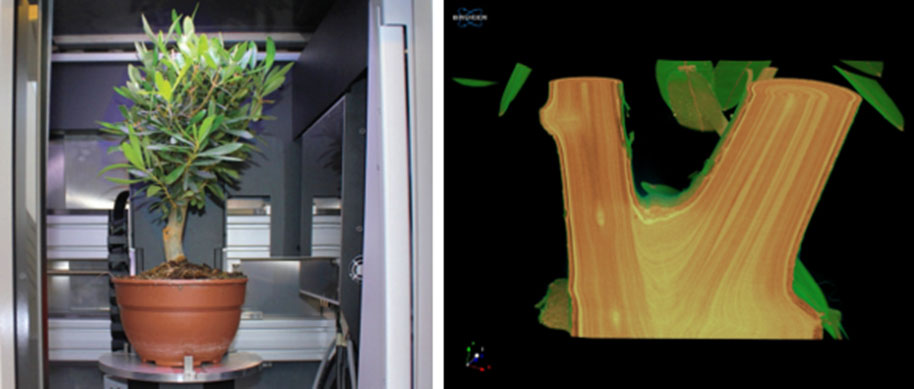

Micro-CTs image relatively large volumes of a sample, a significant advantage over SEM and light microscopy, which are limited to small sample sizes and shallow scanning depths. By capturing statistically representative volumes, micro-CT reduces susceptibility to region-of-interest biases that can otherwise distort results—such as in materials exhibiting a broad distribution of pore sizes or complex biological systems. Figure 3demonstrates the capacity of the Bruker SkyScan 1273 to image a small potted plant as well as fine detail of a wooden stem.

What are possible limitations of micro-CT?

X-ray computed tomography is a transmission-based technique, requiring that a portion of the X-ray beam penetrates the sample while another fraction is absorbed. Since X-ray absorption increases exponentially with both the atomic number of the constituent elements and the thickness of the material, samples with greater density or size demand progressively higher X-ray energies. In practice, this often results in a trade-off, where achieving sufficient penetration comes at the expense of spatial resolution, while also introducing practical considerations such as the need for radiation shielding within the room. Bruker systems are designed to balance high energy and resolution, and their fully self-shielded configuration makes them ideally suited for safe and versatile use in virtually any laboratory setting.

What are the main considerations in choosing a micro-CT system?

Sample size, density, and resolution are key determinants when considering what system will best fit your application.

Various micro-CT systems can scan different sized objects and scan with different energies. To get through larger and denser objects, it is better to have a higher kV source.

The resolution of a scan is determined by the sample size, the pixel resolution of the system, and how small an X-ray spot the source is able to achieve. In general, the smaller the sample, the higher the resolution that can be achieved.

Do you want to see micro-CT results of your sample? We offer a FREE Evaluation Scan

We invite you to see the power of our imaging systems for yourself, risk free, with a free scan performed in our laboratory, or talk with one of our specialists to discuss the best instrument for your application.

610-366-7103