Micro-CT is a versatile tool for non-destructive 3D multiscale analysis, as demonstrated in our study of a peppermill and a peppercorn. Utilizing 3D imaging at various scales allows us to perform a fast, screening method for a low-resolution view of our samples, and to perform a detailed, high-resolution view to visualize internal structures at a micrometer level of resolution.

X-Ray Microscopic Imaging – A Versatile and Multiscale Method

We first performed a high-speed screening acquisition of an entire peppermill at an isotropic voxel size of 80 µm followed by a second dataset of a region of interest focused on the grinding components at a 40 µm voxel size. Finally, we removed a peppercorn from the peppermill and acquired a high-resolution dataset using our SkyScan 1272 at an isotropic voxel size of 2 µm.

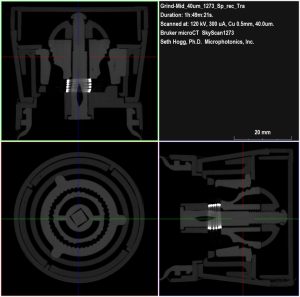

As shown from Bruker DataViewer in Figure 2, our high-speed screening dataset of the entire peppermill provided data on the individual peppercorns as well as the different components physically present in the container, including the hardened plastics comprising the grinding surfaces and the metal spring used to maintain contact between the grinding plates. Using the continuous imaging mode available on the SkyScan 1273, the acquisition time for the entire peppermill screening dataset was about twenty minutes.

Knowing that the grinding mechanism is of further interest, we used the SkyScan 1273 to acquire a higher resolution dataset focusing solely on the top of the sample to provide additional detail on this region.

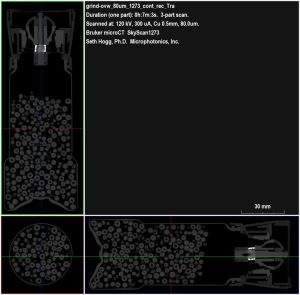

Figure 3: Planar 2D high-resolution views through the peppermill grinding componentsMoving in from our overview imaging of the entire peppermill, Figure 3 highlights the enhanced detail captured of the package closure and grinding mechanisms. While the spring is evident in the dataset due to the much higher attenuation of X-ray energy by metals resulting in the bright white signal, a color difference also exists between the package lid and the grinding components. Since the grayscale brightness of any micro-CT dataset is impacted by local density, the brighter signal in the grinding components suggests the manufacturer utilized a stronger and more wear resistant plastic to withstand the rigors of mechanically crushing peppercorns. For this dataset, we enabled the helical imaging mode available on the SkyScan 1273. This can be useful for samples comprised of both metal and plastic as the helical imaging mode helps to reduce metal streaking artifacts in resulting datasets. Even though the helical imaging mode is slower, the total acquisition time for this dataset was a little less than two hours.

Moving up more than order of magnitude in resolution, we also extracted and imaged a single peppercorn using our high-resolution SkyScan 1272 CMOS Edition.

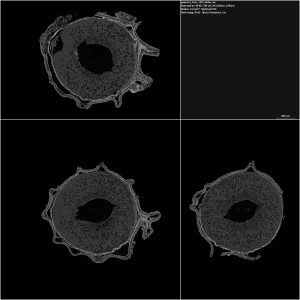

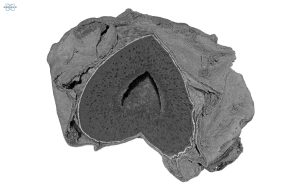

Using an isotropic voxel size of two micrometers, Figure 4 highlights the hidden details captured in an individual peppercorn with apparent density differences between the wrinkled exterior surface and the porous interior core.

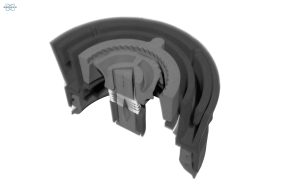

When we view the peppermill dataset in 3D with CTVox, we gain a deeper understanding of the location and local density of components used to mill peppercorns in this device (Figure 5). From the higher resolution VOI view, we also observe areas of porosity within some of the plastic molded components arising from defects during the molding process.

Using CTVox, we digitally sliced into the peppercorn sample to reveal the inner structures, as shown in Figure 6. This view affords us the ability to inspect the size of the inner hollow core, the pattern of porosity within the core of the peppercorn, the dense coating on the surface of the core, and the wavy outer surface structure containing pockets of air.

From our reconstructed SkyScan 1273 dataset focusing on the grinder as a volume of interest, we imported the voxel-based dataset into Simpleware ScanIP software with the CAD add-on module to segment into three individual volumetric models based on density. These models included the spring, the grinding components, and the lower density exterior package plastics. Maverick Render Indie then allowed us to apply colors and textures to the model, as shown in Figure 7.

Conclusion

Micro-CT is a versatile technique that may be utilized both as a fast, screening method for a low-resolution check on samples as well as a detailed, high-resolution view with micrometer level resolution allowing us to visualize structures we never realized existed previously.

We hope you find this Image of the Month article informative and encourage you to subscribe to our newsletter and social media channels in preparation for the continuation of our Image of the Month series next month.

Scan Specifications

| Sample | Peppermill – Overview | Peppermill – Grinder VOI | Isolated Peppercorn |

| Voltage (kV) | 120 | 120 | 60 |

| Current (µA) | 300 | 300 | 100 |

| Filter | 0.5 mm Copper | 0.5 mm Copper | 0.25 mm Aluminum |

| Voxel Size (µm) | 80 | 40 | 2 |

| Rotation Step | Continuous | 0.3 | 0.3 |

| Exposure Time (ms) | 501 | 501 | 3601 |

| Rotation Extent (deg.) | 360 | Spiral | 360 |

| Scan Time (HH:MM:SS) | 00:21:09 | 01:49:21 | 09:08:06 |

These scans were completed on our Bruker SkyScan 1273 and our Bruker SkyScan 1272 micro-CT CMOS Edition instruments at the Micro Photonics Imaging Laboratory in Allentown, PA. Reconstructions were completed using NRecon 2.0 while visualization and volumetric inspection of the 2D and 3D results were completed using DataViewer and CTVox. The peppermill grinder and peppercorn datasets were converted to STL volumetric models using Synopsys’ Simpleware ScanIP software with the CAD add-on module (Synopsys, Inc., Mountain View, USA) before 3D rendering using Maverick Render Indie (Random Control, Madrid, Spain).

Would you like your work to be featured in our monthly newsletter? If so, please contact us by calling Seth Hogg at 610-366-7103 or emailing seth.hogg@microphotonics.com.

References

*Simpleware software (Synopsys, Inc., Mountain View, USA) enables you to comprehensively process 3D image data (MRI, CT, micro-CT, FIB-SEM…) and export models suitable for CAD, CAE and 3D printing. Use Simpleware software’s capabilities to visualize, analyze, and quantify your data, and to export models for design and simulation workflows. Simpleware™ is a trademark of Synopsys, Inc. in the U.S. and/or other countries.