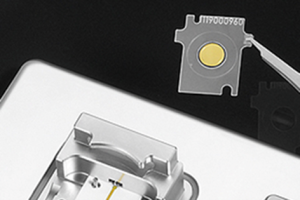

Quartz Crystal Microbalance (QCM) and Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) instruments are used to measure changes in mass on a quartz crystal sensor’s surface (Figure 1) in real-time. Since the 1960s, QCM has been used for precise monitoring of thin films and surface interactions for thin film deposition monitoring, surface science studies, biosensing, electrochemistry, polymer analysis, environmental monitoring, drug discovery, and food science.

Topics below:

- What is the typical setup for a QCM-D experiment?

- Important Considerations During QCM-D Experimentation

- How many times can I use a QCM-D sensor?

- How can I tell if I have a rigid Sauerbrey-type layer?

- How does QCM-D measure both mass and viscoelastic properties?

- Can QCM-D be used in combination with other techniques?

What is the typical setup for a QCM-D experiment?

A typical QCM-D setup includes a QCM-D analyzer, a quartz crystal sensor, and a flow cell or chamber for introducing liquids (Figure 2).

The flow cell allows for real-time monitoring of liquid samples (such as buffer solutions, cells, or biomolecules) as they come into contact with the sensor surface. The analyzer monitors the changes in frequency and dissipation in real-time, while a computer controls the setup and records the data.

A typical experiment includes establishing a stable baseline in background solution (e.g., a buffer in which the sample is dissolved/suspended), followed by switching to the sample solution and monitoring the surface adsorption (negative frequency shift) until the surface is saturated. Lastly, once the surface has been saturated (no more shift in frequency), switching back to background solution and following potential rinse-off of loosely bound sample from the sensor surface completes the setup.

Important Considerations During QCM-D Experimentation

When conducting QCM-D experiments, several key factors should be considered to ensure accurate and meaningful results. Environmental conditions such as temperature, humidity, and liquid properties (e.g., viscosity, pH) can significantly affect the measurements, so it’s important to maintain a stable environment.

Sensor preparation is another crucial step. Proper cleaning and surface functionalization are necessary to avoid contamination and ensure reproducible results. Additionally, understanding the viscoelastic properties of the material being studied is essential, as dissipation measurements are especially sensitive in liquid environments. The concentration and flow rate of the sample solution can also influence the results, particularly for experiments involving biomolecules or complex interactions. It’s also important to ensure that the sensor is properly calibrated, and that the data analysis accounts for factors such as signal noise, drift, and baseline shifts, to avoid misinterpretation.

………………………………………………………

READ MORE about QCM-D instruments

………………………………………………………

How many times can I use a QCM-D sensor?

Indefinitely! Essentially, a QCM-D sensor can be used if it is physically sound, i.e., not broken, cracked, or chipped. The sensor surface can be sufficiently regenerated by cleaning between uses.

The sensor can be kept sound by careful handling, which is very much application dependent. Several options are available for cleaning the sensor surface, such as: surface oxidation by means of plasma or UV-ozone treatment; ultrasonication; piranha solution; base piranha solution; and surfactants (e.g., SDS, tween). Organic solvents may be used for the sensor but are not suitable for the quartz chip.

How can I tell if I have a rigid Sauerbrey-type layer?

A rigid layer does not deform due to the sensor oscillation and therefore dissipates little-to-no energy.

Rigid layer adsorption is thus characterized by a significant frequency and insignificant dissipation shift. In liquids, most rigid layers dissipate a small amount of energy due to hydrodynamic effects caused by changes in surface roughness. As a rule of thumb, layers with a dissipation response that is within 10% of the frequency shifts can be considered rigid, and the Sauerbrey relation gives an adequate estimation of the adsorbed mass.

How does QCM-D measure both mass and viscoelastic properties?

QCM-D measures both mass and viscoelastic properties by monitoring changes in frequency and dissipation (Figure 3). The frequency shift is directly related to the mass of an adsorbed material, with the Sauerbrey equation providing a link between the two.

Dissipation, which can be interpreted through the half-bandwidth of the oscillation peak, reflects how much energy is lost as the quartz crystal oscillates, offering insights into the viscoelastic properties of the material—higher dissipation indicates a more viscous or elastic material, while lower dissipation suggests a more rigid layer. Dissipation is especially useful in liquid environments, where materials can exhibit significant viscoelastic behavior, while in gaseous environments, dissipation is usually negligible. Together, these two measurements allow QCM-D to provide a comprehensive analysis of both the amount and behavior of the adsorbed material, making it particularly useful for studying soft materials, biomolecular interactions, and complex thin films.

Can QCM-D be used in combination with other techniques?

QCM-D can be combined with techniques like microscopy and electrochemistry to provide more comprehensive data. For example, microscopy is excellent for determining the surface coverage of cells, bacteria, particles, or other structures, while also providing a visual representation of the material or biological interactions. This allows for detailed insights into the coupling behavior through the QCM-D signal. Electrochemistry can be used to study the mass and mechanical properties of electrochemically induced surface reactions or layers, complementing the QCM-D data by revealing how the material interacts with an electrical stimulus. Combining these techniques with QCM-D enables a more complete analysis of surface properties, molecular dynamics, and material or biological behavior.

……………………………………………………………………………………………………………………….

EMAIL Steve, our QCM specialist, to see if the technology will work for your application

……………………………………………………………………………………………………………………….

3T Analytik develops innovative technological solutions for the monitoring of molecular binding and interactions and surface associated phenomena. Quartz Crystal Microbalance (QCM) and Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) technology is used to measure changes in mass on a quartz crystal sensor’s surface in real-time. The instruments from 3T ensure precise, easy surface analysis technology for established and emerging industrial and academic applications.